Glass Lamination

Laminated safety glass and solar panels seem to be very similar as both are laminated products that use a polymer for bonding, which becomes transparent when finished. The glass industry uses the term "interlayer" for this polymer while the PV industry calls it "encapsulant" for obvious reasons (the solar cells are hermetically encapsulated). Other than that it appears as if the same lamination technique used in one industry could also be used in the other. Interestingly that is not true. The glass industry uses mainly autoclaves for lamination. But anybody who tried to make solar panels with a vacuum bag in an autoclave knows that it leads to a massive amount of broken solar cells. And for some reason vacuum lamination has not entered the glass world so far, because of the size some glass panels can have, the differences in the polymer material properties, the way it laminates and the specifications of the finished product that have to be met.

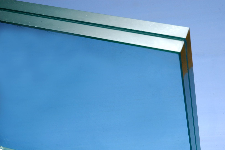

SM InnoTech has shown that vacuum lamination can also be used in the glass industry successfully with the end product meeting all common requirements of this industry. Have a look.

PV Module Lamination

SM InnoTech has re-invented the vacuum laminator. This change is a bit like the transition from horse drawn carriages to motorized cars: The idea of putting four wheels under a frame is the same but everything else changed.

SM InnoTech eliminated the huge vacuum chambers. These used to be made from either cast iron or heavy welded steel - expensive to ship and difficult to get through doors. SM InnoTech shows us that the vacuum can be created much smarter. The immediate benefit is that electrical cables are now in atmosphere and no longer exposed to the acidic vapors when EVA is laminated. The temperature sensors can be replaced while the laminator is hot. This alone is a huge advantage as cooling down a laminator takes about 8 hours. One lost shift, imagine that. With the huge and heavy vacuum chambers gone, the laminator can now be built in practically any size and at a reasonable price. How about shipping the laminator in standard containers? Unheard of in the world of big laminators. SM InnoTech made it happen. Now, go on and learn all about the details.