Electroluminescence (EL) Systems and LED Sun Simulators for the Photovoltaic Industry

About MBJ Solutions

MBJ Solutions manufactures electroluminescence inspection systems and sun simulators with innovative features for module production lines. The company was founded in 2009 and has sold hundreds of electroluminescence inspection systems since 2010.

In 2015 MBJ added a sun simulator / flash tester to their product portfolio that can be integrated with an EL unit to form a complete backend characterization solution. The design is clever as it allows modules entering the machine and being measured at conveyor height. The machine footprint is barely larger than the modules. The sun simulator features an LED array to illuminate the module. Say goodbye to frequent lamp replacements and non-uniformity testing.

With a strong background in image processing, camera technology, illumination and software development, MBJ has developed a software package that provides automated defect detection without the presence of an operator. The EL inspection product spectrum includes high-res and high-speed models. The sun simulator features a flash duration of 200 ms, which allows testing high-efficiency modules.

MBJ is also a manufacturer of proprietary custom equipment. If you have an idea that you want to turn into a piece of equipment to boost the productivity of your line, MBJ would be pleased to develop the system together with you. Customization of the standard equipment below is also possible.

General Product Specifications, EL and Sun Simulator

EL Systems

- Inline configuration - modules entering and being measured at conveyor height

- Measurement of modules, cell strings, cells

- Module types: crystalline / thin film

- Active area: max. 1,360 x 2,640 mm

- Max. module size: 1,400 x 2,700 mm

- Contacting: automated / manual

- Defect detection: software / operator

- Software: proprietary, developed by MBJ

- Built to last: Compatible with M12 size cells

Sun Simulator

- A+A+A+ rated to match IEC 60904-9 Ed. 2 and 3

- Active area: max. 1,360 x 2,640 mm

- Max. module size: 1,400 x 2,700 mm

- Manually operated and fully automated versions

- Light source: LED array, certified by TUV, Germany

- >10 million flashes @ 1,000 W/m2

- Long flash pulse to measure high efficiency modules

- Optional front and back illumination for bifacial modules

- Built to last: Compatible with M12 size cells

General

- All systems can be modified to meet custom requirements

- MBJ designs proprietary inspection equipment based on specifications from customers

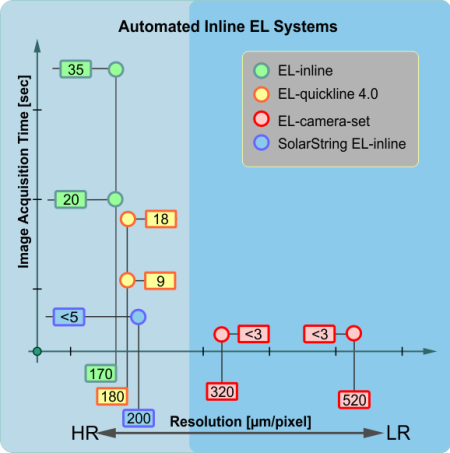

Select Your Automated Inline EL System

The chart below lists the four available automated inline EL systems sorted by their resolution from high (HR) to low resolution (LR). The better the resolution and the larger the measurement area, the higher the acquisition time. The first two in the chart (green, orange) are designed as inline systems for an automated production line. The third (red) is a set of cameras that can be integrated in any existing third party sun simulator. The fourth one (blue) is an EL system to check cell strings before they go to the module layup station.

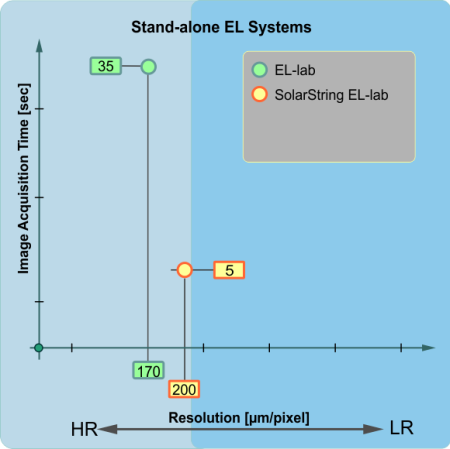

Select Your Stand-Alone EL System

The chart below lists the four available stand-alone EL systems sorted by their resolution from high (HR) to low resolution (LR). The first (green) is the system with the highest resolution for modules in MBJ's product line-up. The second system (blue) is designed as entry level system for small production lines and for installers. The third system (orange) is ideal for a string repair station in a module production line. The fourth (red) is used for testing solar cells in the lab or to spot check procured cells.

Application

- Fully automated system for all module types including modules with PERC cells, bifacial and thin film modules

- Can be integrated with an EL system to form a fully automated inline backend measurement solution

- Available in four sizes to accomodate modules with cell sizes from M2 to M12

Specifications

-

Module Type: crystalline, thin film, framed, frameless

-

Active Area: up to 1,360 x 2,640 mm

-

Module Size: up to 1,400 x 2,700 mm

-

TUV certified LED light source

-

Rating: A+A+A+ IEC 60904-9 Ed.3

-

Irradiance: 200 - 1,200 W/m²

-

Light Source: LED array, >10 million flashes @ 1,000 W/m2

-

Non-Uniformity: < +/- 1%

-

Repeatability of Pmax: <0.1%

- Flash Pulse @ 1,000 W/m² : 200 ms

- Flash Pulse @ 1,200 W/m² : 100 ms

Spectral Range

- 300 - 1,200 nm (IEC 60904-9 Ed. 3) extended spectrum

Options

-

Module orientation: short end leading, long end leading, to be specified

-

Hipot and grounding test integrated

-

2nd LED array for bifacial modules

-

Operator desk with PC and label printer

-

Light tower

-

UPS

Specifications Hipot / Grounding Test

- Test Voltage: up to 11,000 VDC

- Test Current: 3 - 30 A

- Test Time: 0.1s - 999s

- Contacting Unit: Carbide metal probe actuated pneumatically

Application

- Complete backend solution, combines EL, sun simulator, hipot and grounding test in one connected inline system

-

Module Type: crystalline, thin film

-

Active Area: max. 1,360 x 2,160 mm

-

Max. Module Size: 1,400 x 2,250 mm

Specifications EL System

-

Cycle time: <40s (standard), <20s (high speed)

-

Defect Detection: software

-

Resolution: 180 µm/pixel

-

Image Acquisition Time: <18s (standard), <9s (high speed)

Options

- Module orientation: short end leading, long end leading, to be specified

Specifications Hipot / Grounding Test

- Test Voltage: up to 11.000 VDC

- Test Current: 3 - 30 A

- Test Time: 0.1s - 999s

- Contacting Unit: Carbide metal probe actuated pneumatically

Specifications Sun Simulator

-

Rating: A+A+A+

-

400 - 1,000 nm (IEC 60904-9 Ed. 2)

-

350 - 1,100 nm (IEC 60904-9 Ed. 3)

-

350 - 1,200 nm (optional)

-

Irradiance: 200 - 1,200 W/m²

-

Light Source: LED array, >10 million flashes @ 1,000 W/m2

-

Repeatability of Pmax: <0.1% (absolute)

-

Flash Pulse: 200 ms @ 1,000 W/m²

Application

- MBJ's most flexible EL system

- EL before/after lamination, after framing

- Variable resolution, variable measurement time

- Automated image processing

- Automated test report function

Specifications

- Module Type: crystalline, thin film

- Active Area: max. 1,360 x 2,160 mm

- Max. Module Size: 1,400 x 2,250 mm

- Defect Detection: operator, software

- Resolution: 180 µm/pixel

- Image Acquisition Time: 18s (standard), 9s (high speed)

Options

- Module orientation: short end leading, long end leading, to be specified

- Software license for offline PC

- Software for rework area

- Automatic barcode-reader

- Automatic contact unit (pre lamination)

- Automatic decontact unit (final inspection)

- Software and hardware for diode test

- Several interfaces like Profibus, CC Link, and others

Application

- Hi res EL measurement in mass production, standard or hi-speed

- EL before/after lamination, after framing

- Fully automated inspection, no operator

- Automated image processing

- Automated test report

Specifications

-

Module Type: crystalline, thin film

- Active Area: max. 1,360 x 2,160 mm

- Max. Module Size: 1,400 x 2,250 mm

- Loading: automated, auto contacting

- Defect Detection: software

-

Resolution: 170 µm/pixel

-

Image Acquisition Time: <32s (standard), <20s (high speed)

Options

- Standard or high speed versions

- Software for additional workstation

- Software for shunt detection

- Software and hardware for diode test

- High voltage power supply for thin film

- Barcode reader

- Automated cell measurement

- Automated contact unit

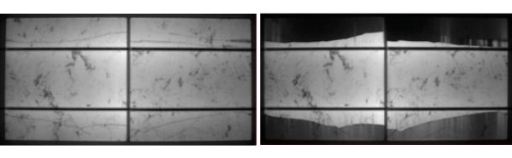

Application

- MBJ's highest resolution system

- Detects: micro cracks, dark areas, finger interruptions even on multi-crystalline cells

- Automated test report function

Specifications

- Module Type: crystalline, thin film

- Active Area: max. 1,360 x 2,160 mm

- Max. Module Size: 1,400 x 2,250 mm

- Loading: manual

-

Defect Detection: software / operator

-

Resolution: 170 µm/pixel

-

Image Acquisition time: 35s

Options

- Software for additional workstation

- Software for shunt detection

- Software and hardware for diode test

- High voltage power supply for thin film

- Barcode reader

The certification lab

TÜV Rheinland

is using this system.

Application

- OEM unit to be integrated in existing sun simulators from various manufacturers

- Defect detection by operator

Specifications

- Module Type: crystalline, 60 and 72 cells

- Defect Detection: operator

-

Module size: 1,050 x 2,050 mm

-

Resolution: (HR) 320 µm/pixel, (LR) 520 µm/pixel)

-

Image Acquisition Time: (HR) 5s, (LR) 3s

Options

- Fully automatic integration into test sequence

- Software and hardware for diode test

- Software for shunt detection

- Software licence for offline workstation

- Configurable from 8MPixel up to 60MPixel

Application

- Inspection of solar cell strings

- Integration in module layup stations

- Detecting micro cracks

- String position for layup

- Detecting soldering problems

- Checking repaired strings

Specifications

- Cell Types: mono- and multi-crystalline

- String Length: up to 12 cells, 5" or 6"

- Loading: automated inline / manual

- Defect Detecion: software / manual

- Resolution: 200 µm/pixel

- Image Acquisition Time: < 5s

Options

- 2D measurement

- Edge inspection

Where is MBJ Solutions located? MBJ is located in the town of Ahrensburg, Germany, near Hamburg. Hamburg's airport (HAM) is about 33 minutes away by car, depending on traffic. Hamburg is the 2nd largest city in Germany with the largest harbor on the river Elbe.