Lightly Used Performance Lamination Line

Offer

A fully automated lamination line manufactured by SM InnoTech in Germany with two stacked incapcell 43-20 vacuum laminators and one cooling press. Only approx. 1,000 hours of runtime. Has been used by a German module manufacturer who went out of business.

What can it laminate?

- Standard modules (glass/EVA/backsheet).

- Double glass modules (e.g. bifacial modules).

- Flexible thin film modules.

- Any type of encapsulant.

Special features

Each laminator is equipped with:

- 2 heating platens, a lower and an upper one.

- 2 pressing membranes.

- A rotating (upper) release sheet.

Manufacturing capacity

For crystalline modules: Standard PV modules up to 60 cells per module (size approx. 1,000 x 1,600 mm per module), 4 modules per run. Manufacturing output depends on parameters like module efficiency, lamination cycle time, achieved productive time.

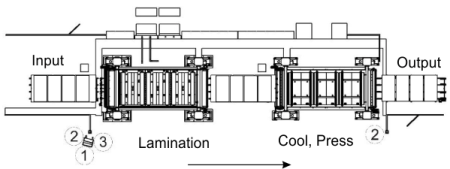

The photo shows the entire line. Modules enter from the left and are arranged on the input conveyor table. From there they are moved into either the lower or upper laminator. On the right side of the photo in the background is the cooling press. Pressing takes less time than a typical lamination cycle and therefore one press serves both laminators. The line is fully automated.

Plan view of the lamination line

Modules move from left to right. The line is capable of laminating crystalline modules of any kind as well as flexible and rigid thin film modules. Shown here is the line producing batches of four 72-cell crystalline modules.

Included Components

1 Input conveyor with scissor lift

2 laminators incapcell 43-20, stacked on top of each other, lamination area each 4,520 x 1,740 mm, each with lower and upper heating platen, 2 membranes, 2 transport sheets, 2 rotating release sheets, temperature uniformity ±2°C.

1 Output conveyor with scissor lift

1 Cooling press with upper and lower cooling plates, 1 membrane

1 Output conveyor without scissor lift for cooling press

2 Vacuum pumping stations, one for each laminator

1 Vacuum pumping station for cooling press

Electrical cabinets and 2 control consoles

1 Safety fence partially surrounding the equipment and 2 doors with proper LOTO wiring

1 Light curtain along the right side of laminators and cooling press

3+ separate roller tables

Documentation and software

Note: This list is a snapshot of what we know about the line so far and may not be complete.

Seller & Location

Hörmann Verwertungen GmbH & Co. KG, Germany